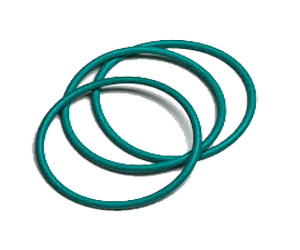

An O-ring is a doughnut-shaped object, or torus. The opposite sides of an O-ring are squeezed between the walls of the cavity or "gland" into which the O-ring is installed. The resulting zero clearance within the gland provides an effective seal, blocking the flow of liquids or gases through the gland's internal passage. We are manufacturing a wide range of Viton O ring custom model products according to customer specification. we use only the finest quality of raw materials to create a quality of Product.

Viton is a brand of synthetic rubber and fluoropolymer elastomer commonly used in the manufacture of chemical resistant O-rings, seals and gaskets. The material is classified as ISO 1629 standards. Viton is known for its high density. Viton sealing products are resistant to high temperatures, petroleum products, a wide range of solvents and chemicals. In general, this material is compatible with hydrocarbons, but incompatible with acetones, ketones, steam, hot water, and organic acids. Viton is also know as FKM. FKM is a well-known high-performance rubber that has excellent resistance to high temperature, ozone, weather, oxygen, mineral oil, fuels, hydraulic fluids, aromatics and many organic solvents and chemicals.

Viton seals also have some chemical resistance and are ideal in pumps used for agriculture, pest control, disinfection, mold remediation and lawn care sprayers because some of the compounds used are hydrocarbon resistant. Another reason why these types of applications may be more suitable for Viton O-rings is because of their higher ability to withstand sunlight and other environmental conditions. Lowest temperature resistance is normally not favourable and for static applications is limited, although in certain situations it is suitable down to -40°F (-40°C). Gas permeability is very low and similar to that of butyl rubber. O-rings are used in seals that have to maintain consistent performance in a wide range of temperatures. In industries ranging from aerospace to oil refining, there are systems that reach high temperatures, which can quickly destroy or damage seals. Viton O-ring's are the preferred material for systems that regularly reach these maximum temperatures. Not only do these parts need to withstand high temperatures, they also need to withstand corrosive chemicals and minerals. These O Ring's are used in the industries like Aerospace, Heavy-duty trucking, Transportation, Appliances, Electronic processing, Food and beverage processing, Oil and gas drilling etc.

Asean Rubber offers fluorocarbon O-rings, seals and gaskets manufactured from Viton. We can provide Viton o-rings, seals and gaskets in all standard sizes as per requirement, as well as in custom configurations, We always try to meet the specific needs of your application. To discuss your viton rubber products requirement Contact us now.